The study, “Comprehensive Multilevel Cycle of Stainless Steel in 2015” was led by Barbara Reck, Senior Research Scientist at Yale University and is based on a comprehensive investigation into how stocks of recycled stainless steel flow from scrap into new material.

Steel is the world’s most recycled material and by recycling scrap, producers can avoid the additional energy consumption and carbon dioxide emissions required to process virgin ore materials.

Camilla Kaplin, Outokumpu’s senior manager - environment, said: “While producing stainless steel is energy intensive, it creates products and infrastructure that last many decades, so it can be seen as an investment in energy. For example, New York’s Chrysler building and London’s Savoy hotel both have stainless steel panels that look just as good today as when they were built in the 1920s”.

“As a producer of stainless steel, we work hard to reduce the carbon footprint of our products. We use at least 85 percent recycled content in our production, which is the highest on the market. That makes a big difference to our carbon footprint – according to Germany’s Fraunhofer Institute, every tonne of austenitic scrap used in the production of stainless steel saves 4.3 tonnes of CO2 emissions.”

Kai Hasenclever, the International Forum of Stainless Steel’s (ISSF’s) Director Economics & Statistics and Long Products, and Team Stainless project leader commented:

“Stainless steels support many essential applications in our modern world from transportation, buildings, bridges and water pipes to medical uses and food preparation. As the focus on sustainability intensifies there is an increasing need to quantify the material life cycle of stainless steels and their efficiencies from production to fabrication, manufacturing, use, recycling and disposal.”

Stainless steel life cycle: key facts from the study by Yale University

- 41.8 million tonnes of stainless steel were produced in 2015, the year of the report

- 20 years – the average lifespan of stainless steel products

- 85% of stainless steels are recycled at the end of their life

- 56% are remelted as new stainless steels, whereas 29% become carbon steels

- Outokumpu uses at least 85% recycled content in its stainless steel, compared with a global average of only 44%

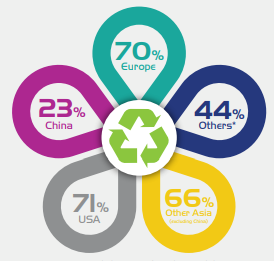

- Recycled content in stainless steel varies widely around the world:

- North America 71%

- Europe 70%

- China 23%

- End-of-life recycling rates are already high for stainless steel although there’s still room for improvement – the following levels of stainless steel are recycled from different industries:

- Household appliances 80%

- Building and infrastructure 85%

- Transportation and industrial machinery 90%

Download the ISSF’s summarized report for the key facts and figures

Comparative recycled content of stainless steels by region according to the Yale study.

In many world regions, recycled content in new stainless steels was much higher than the 44% global average scrap ratio suggests. The world average is strongly impacted by the dominance of China’s production with low recycled content (23%).

![]()

Outokumpu’s stainless steel contains the highest proportion of recycled content, over 85%, on the market.